Eye on Display goes under the bonnet of one of the country’s biggest suppliers of banners to find out how it’s done.

Many thanks to Scott Conway of Venture Banners for his insights and Expert Advice

Scott Conway from Venture Banners

A friend and client recently quizzed me on our company name; ‘you may have started out just supplying banners’, he asked, ‘but you supply so many other materials and products now, is the name Venture Banners still appropriate?’.

He had a point.

When we started in 2008 that’s all we did, but over time we have evolved to incorporate new materials and products, we’ve invested heavily in new grand format machinery and incorporated new printing disciplines on rigid and textile materials, but the fact is, we still print a lot of banners.

I did some digging and on average we print around 10,000 square metres of banners every month and that’s made up of all types of jobs from small one offs to larger orders and larger banners.

Banners make up for around 40% of our work.

So with that in mind, I thought you’d like to know how your banner orders are produced and for that we need to go down to the basement.

The Materials

We print onto several banner materials, starting with our standard 440gsm. This material is one we’ve used for over ten years and it’s perfect for banners. It has good strength, is a nice white (some materials are very yellow) and it gives great colour vibrancy.

We also print onto a 340gsm Mesh, which is a premium product designed for building wraps, so it’s more than at home on Heras Fencing and scaffolding. The beauty of this product is that it’s 75% closed, so the image doesn’t disappear when there’s light behind it, but still allows a large volume of air to move through the banner, protecting whatever it’s attached to.

Both these materials are available in PVC-Free guise as well.

We also print onto a 500gsm coated material which is predominately used for outdoor tension frame systems and also onto a heavy-duty double sided blockout material which is perfect for lamp post banners and the like.

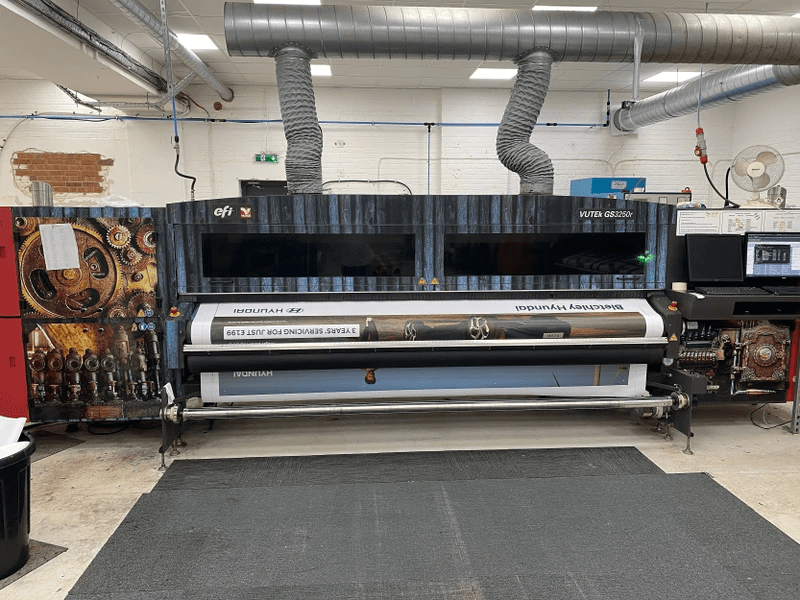

The Printers

Meet Bert and Ernie, two EFi GS3250r roll-to-roll machines. 3.2m wide; six colour with light cyan and light magenta to give amazing colour gamut and great skin tones; UV curing and 166 square metres of printed material per hour at 600dpi

These machines are ten years old now and were pre-LED curing, so they have a cooled platen to eliminate material warping and that platen is also removable so you can print mesh without a liner. They also have automated double-sided printing capability.

They were £350k each and the absolute cutting edge when they were new. They are looked after better than my children and so still produce industry-leading quality print for your banners.

The Finishing

You can’t print the volume of banners we do without having some serious finishing kit and we’ve got some of the best and fastest available.

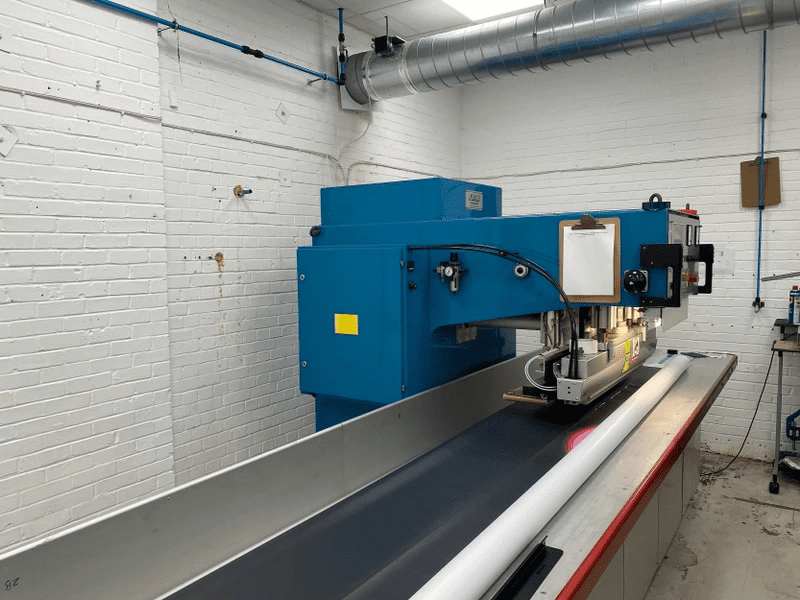

Two hot-air hem welders that seal your hems at 720 degrees centigrade and run at 20 linear metres per minute. Welding the hems gives them enormous strength.

A 12m-long Fiab High-Frequency Welder for pole pockets and large joined banners that will literally join the material by bouncing the molecules around until they fuse together, this once again gives our pole pockets enormous strength.

A finished eyelet

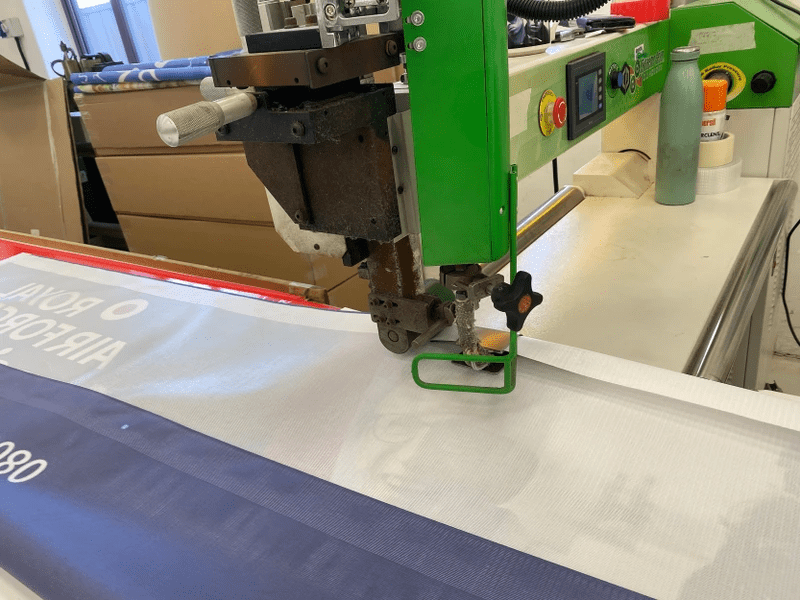

Eyelets

Two laser-guided eyelet machines. We use nickel-plated eyelets to stop eyelet bleed that you sometimes get with low-quality or brass eyelets.

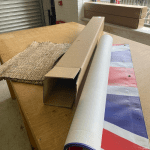

A Banner Ready to be Dispatched, with Recycled Cardboard Insert

Packing

Where possible, if your banner is below 1350mm on the shortest edge, we will pack your banner order in a cardboard box with recycled cardboard as the protective fill material.

Conclusion

Although we do other materials and we’ve got some exciting new materials coming through in the next few months, banners are still the cornerstone of the business… for the moment.

As for my friend’s original question, I responded by saying that I had flown to Dubai recently with Virgin ‘Atlantic’. If you see the parity. He laughed and said ‘you’re not in that league yet’.

He had a point.